WESTERIA GMBH

Présentation

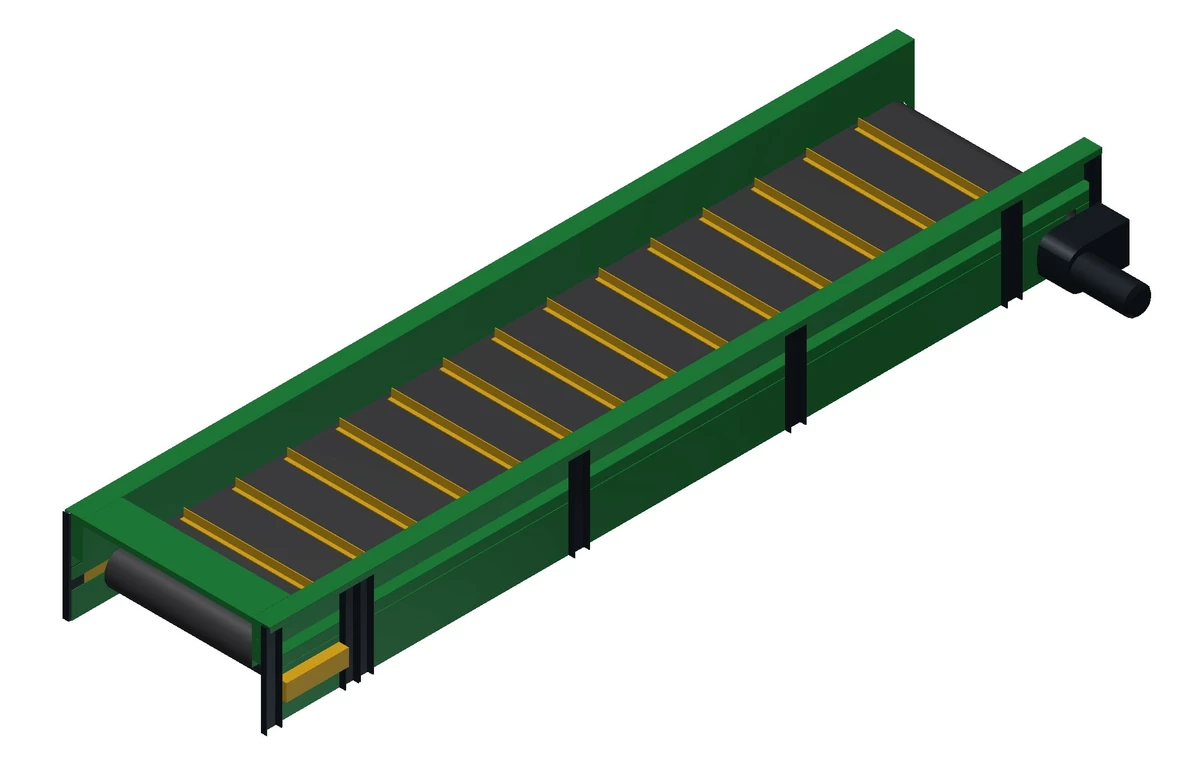

Westeria GmbH se spécialise dans la classification de l'air, le convoyage, le dosage et la distribution pour l'économie circulaire. Basée à Ostbevern, Allemagne, l'entreprise propose des solutions avancées comme les convoyeurs transbordeurs et à bandes, essentiels pour l'efficacité du transport de matériaux. Elle excelle dans la manutention des déchets par fonds mouvants et propose des séparateurs aérauliques et mécaniques pour une séparation précise des matériaux. Ses tamis pour déchets optimisent le tri et la valorisation. Westeria GmbH est un partenaire stratégique pour les professionnels cherchant à améliorer leurs processus de gestion des déchets.

Informations juridiques

| Chiffre d'affaires | 10 à 50 M€ |

| Effectif | 101 à 200 |

| N° TVA | DE126733763 |

Documents

Toutes les actualités :

Classification de l'air, convoyage, dosage, distribution. Votre partenaire pour l'économie circulaire.

Activités de l'entreprise