Document

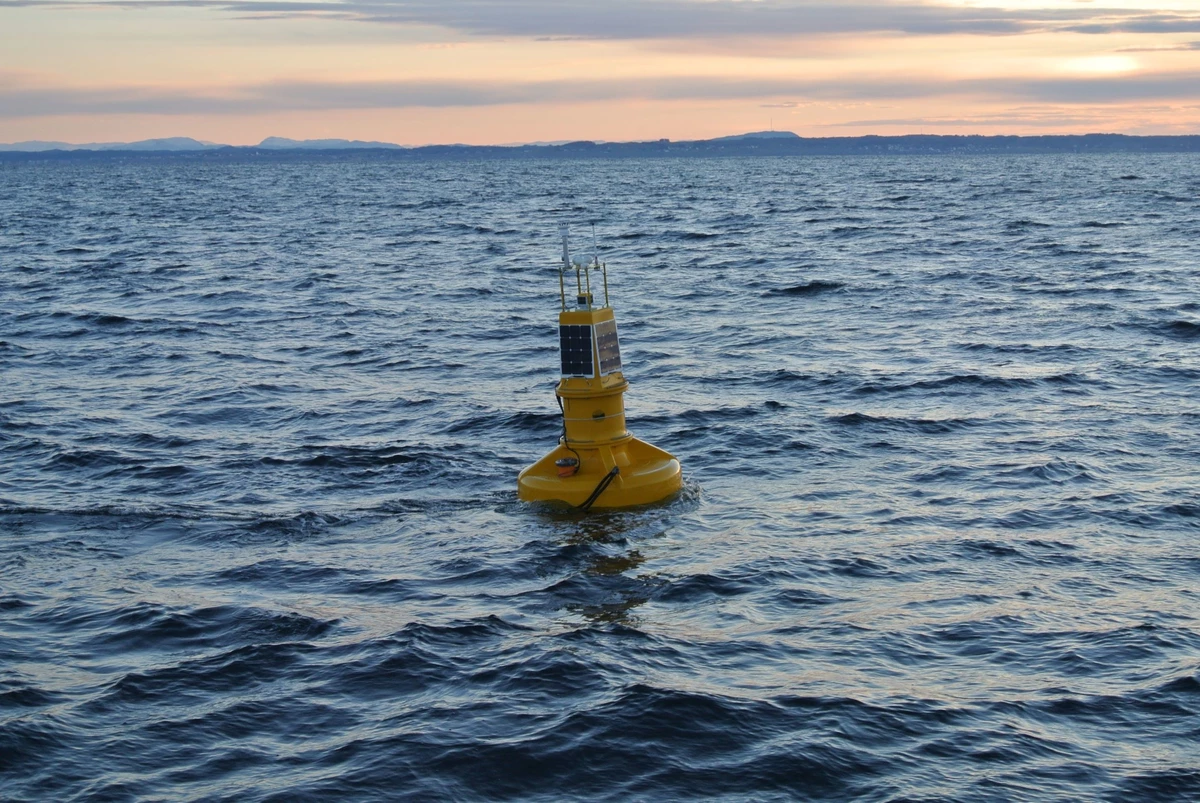

manuel du produit sb-138p sentinel buoy

manuel technique du sb-138p sentinel buoy de tideland

Contenu du document

SB-138P SENTINEL BUOY

Le SB-138P Sentinel buoy est un produit de l'engagement continu de Tideland Signal dans le développement de dispositifs d'aide à la navigation maritime performants, à faible maintenance et rentables. Déployé dans plus de 40 pays, le SB-138P buoy utilise les avantages des derniers matériaux, processus de fabrication et technologies. Il offre une bouée robuste, légère, dotée d'une excellente tenue en station et d'une longue durée de vie, tout en réduisant les coûts d'entretien à long terme souvent associés aux aides à la navigation flottantes.

Caractéristiques

- Polyéthylène stabilisé aux UV – Moulé par rotation pour former un corps sans couture de 9,5 mm d'épaisseur. Grâce à un design de moule unique et un processus contrôlé, une épaisseur accrue est formée aux points de stress majeurs.

- Divisée en trois sections – Une section de flotteur, une section de batterie et une section de nav-aid forment une bouée résistante à l'abrasion et absorbant les chocs, capable de résister aux coups et/ou collisions. La section de flotteur a une surface antidérapante moulée, offrant une précaution de sécurité supplémentaire pour l'entretien en station.

- Sections assorties ou alternées – Facilite la création de bouées de bifurcation, rouges ou vertes selon les besoins. Les bouées cardinales peuvent être assemblées de la même manière, avec des sections jaunes et noires. Les bouées de fairway ou d'eau sûre sont produites à l'aide d'un procédé de graphisme en couleur moulée, aboutissant à un rayage vertical rouge et blanc.

- Force et sécurité à long terme – La section de flotteur est renforcée intérieurement avec des tiges en acier inoxydable connectées à des bagues en acier inoxydable dans les œillets d'amarrage et de levage. Les œillets d'amarrage sont équipés d'une bague d'usure en acier inoxydable remplaçable.

- Stabilité – Obtenue en remplissant la section de flotteur avec une quantité calculée de béton renforcé comme ballast. Ensuite, l'ensemble de la section de flotteur est rempli de billes de polystyrène. Le flotteur est ensuite scellé et placé dans une chambre à vapeur pour agrandir les billes de mousse à leur taille maximale, les fusionnant ensemble. Ce processus aboutit à une pièce solide de polystyrène remplissant complètement tous les vides, empêchant l'entrée d'eau en cas de perforation, ajoutant de la robustesse à une aide flottante déjà solide.

- Puissance – Configuré pour 12V ou 24V nominal, le système d'alimentation pour la lanterne et l'équipement facultatif est logé dans la section de batterie, qui fait également partie de la tour pour la lanterne.

- Section navaid – Dispose de liaisons pour quatre modules solaires de 10 watts de crête ou jusqu'à trois modules solaires de 20 watts de crête et un de 10 watts de crête. Les configurations de modules solaires peuvent varier selon la charge électrique et l'insolation moyenne pour la zone de déploiement. Cette section comprend également un réflecteur passif haute performance interne (10m²) et un garde-lanterne (si nécessaire). L'accès à la section de batterie et à tout l'équipement se fait par une trappe de service résistante aux altérations et étanche, située dans la section navaid.

Détails techniques

- Construction – Moulée par rotation en polyéthylène vierge de densité moyenne stabilisé aux UV, 9,5 mm d'épaisseur.

- Remplissage en mousse – Mousse de polystyrène expansée 16kg/m³.

- Poids à vide – 1 000 lb (454 kg) (y compris deux manilles de 38 mm (1-½ po)).

- Diamètre – 5 pi 9 po (1 750 mm).

- Hauteur du plan focal – 7 pi 6 po (2 290 mm).

- Plan focal étendu en option – 9 pi 6 po (2 900 mm).

- Tirant d'eau – 2 pi 6 po (751 mm).

- Franc-bord – 1 pi (305 mm).

- Submersion – 138 lb/po (24,7 kg/cm).

- Réflecteur radar – 10 m² (bande X).

- Portée radar, nominale – 3 à 4 NM.

- Zone visuelle avec panneaux de repérage (forme de canette) – 17,2 pi² (1,6 m²).

- Zone visuelle avec panneaux de repérage (forme de non) – 16,1 pi² (1,5 m²).

- Couleur de surface – Tel que spécifié.

- Charge d'amarrage maximale – 1 400 lb (636 kg).

- Courant maximal – 6 nœuds.

Amarrages recommandés

- Courant inférieur à 2 nœuds

- Profondeur d'eau (pi) : Chaîne Longueur (Shot) : Taille de chaîne

- 35 : 45 pi (1/2) : 1 1/8 po

- 35-50 : 90 pi (1) : 1 po

- 50-80 : 135 pi (1 1/2) : 1 po

- 80-120 : 180 pi (2) : 3/4 po

- 120-160 : 225 pi (2 1/2) : 5/8 po

- 160-200 : 315 pi (3 1/2) : 1/2 po

- Courant de 2 à 4 nœuds

- Profondeur d'eau (pi) : Chaîne Longueur (Shot) : Taille de chaîne

- 35 : 90 pi (1) : 1 1/8 po

- 35-50 : 90 pi (1) : 1 po

- 50-80 : 135 pi (1 1/2) : 1 po

- 80-120 : 225 pi (2 1/2) : 3/4 po

- 120-160 : 450 pi (5) : 5/8 po

- 160-200 : 450 pi (5) : 1/2 po

- Courant de 4 à 6 nœuds

- Profondeur d'eau (pi) : Chaîne Longueur (Shot) : Taille de chaîne

- 35 : 90 pi (1) : 1 1/8 po

- 35-50 : 135 pi (1½) : 1 po

- 50-80 : 180 pi (2) : 1 po

- 80-120 : 270 pi (3) : 3/4 po

Entreprises concernées :

Produits concernés :

Date d'upload du document :

mercredi 20 octobre 2021